Delta Constructors believes a zero-incident workplace is achievable. It is achievable when expectation, commitment and responsibility are shared. All employees should expect to work in a safe environment where hazards and at-risk behaviors are proactively and systematically identified and eliminated or mitigated.

Delta’s safety culture is integrated into every aspect of our business. We develop safety management processes, teach and train safe work practices and continually track and measure our progress.

Every Delta job description includes learning, applying and following the rules and techniques of safe work practices and incident prevention.

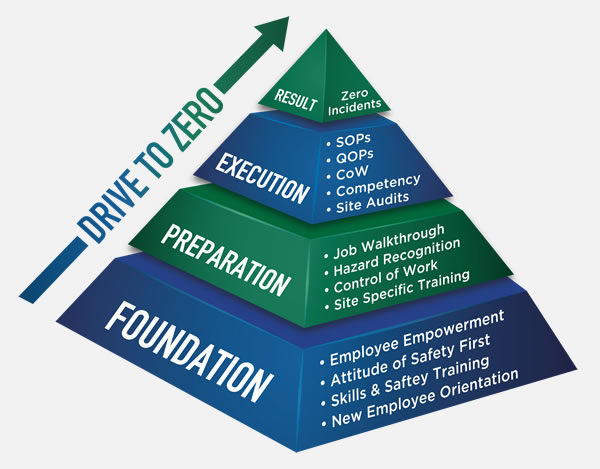

Delta’s drive to zero injuries is built on a strong FOUNDATION with a safety program including New Employee Orientation and Behavior Based Safety protocols.

Through PREPARATION we recognize hazards and mitigate risk before EXECUTION of any work. Lastly, we analyze the RESULTS, capture lessons learned and continually improve safety initiatives based on data trends.

Delta Constructors continually promotes a culture of safety as a core value and accountability is shared across the board.

Safety is a foundational bed rock; it is promoted through Safe Operating Procedures, Stop Work Authority, New Hire Orientation, Short-Service Employee Program, Leadership Training and Engagement, as well as daily field HSE tailgate meetings and weekly HSE toolbox updates.

Our proactive approach, relentless training and a focus on leading indicator assessments ensures we maintain a safe work atmosphere.

Leading by example is an integral component of Delta’s safety culture.

Leadership engagement provides coaching and mentoring to develop Delta’s standards in every level of our organization, giving employees the opportunity to be the best they can be.

The quality of our product is our reputation. Positive outcomes are the results of clear expectations executed by knowledgeable, competent, well-trained people taking pride in their work.

Delta Constructors’ goal is that 100% of our projects are completed exceeding quality standards of our clients and regulatory agencies. Delta’s quality process includes:

Quality Management System (QMS) is the backbone that guides Delta Constructors’ quality program for all projects. The QMS is used to ensure consistency in project set up, execution, and closeout around a single quality standard.

Quality Operating Procedures (QOPs) define the quality requirements for each project. These procedures are a bit more dynamic and can be modified on a project-by-project basis to ensure conformity.

Work Instructions provide clear, step-by-step information on how to inspect and record actual quality performance for specific job activities. Those responsible for performing and inspecting the work must review and acknowledge their understanding of the Work Instructions prior to beginning any task.

Designed by Alaska Search Marketing, LLC.